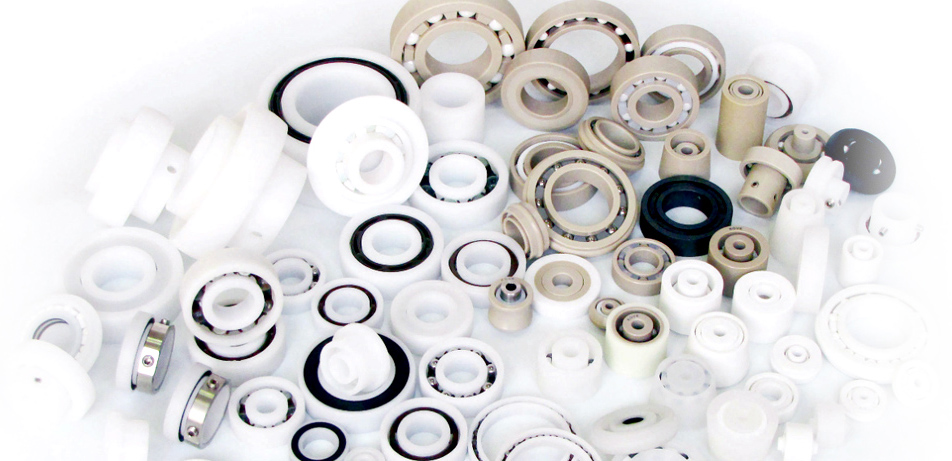

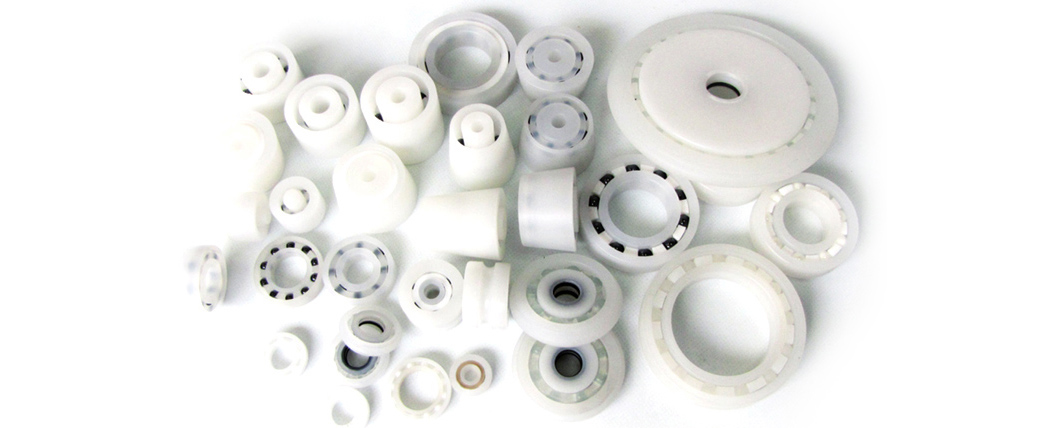

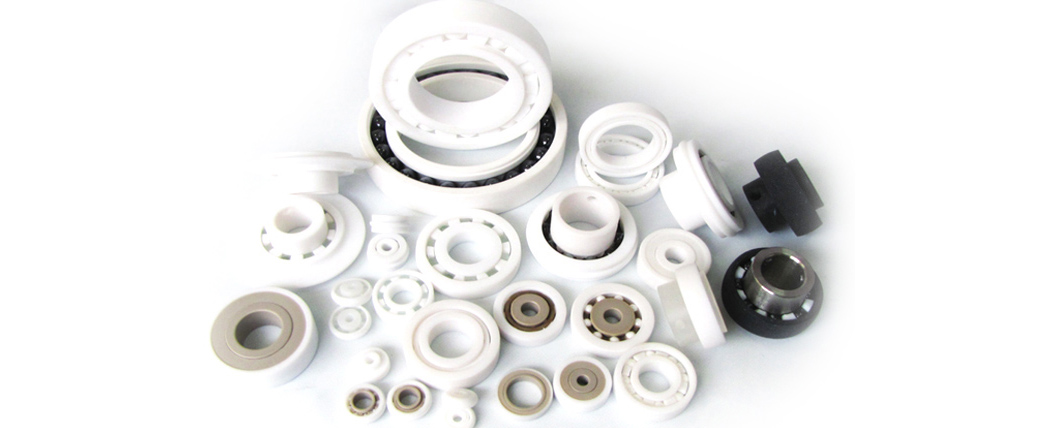

1、KOVE plastics bearings range includes precise engineering plastics bearings, anti-corrosion bearings, acid/alkali-resistant plastics bearings, high temperature resistant plastics bearings, engineering plastics UC bearings and housing.

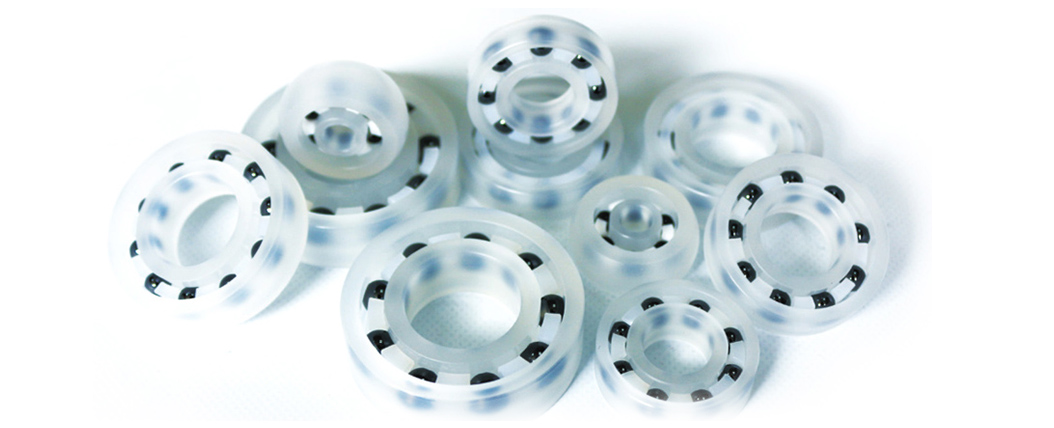

2、The inner and outer rings of precision engineering plastics bearings are usually made with POM and PEEK, rolling elements with glass balls, stainless steel balls and ceramic balls, cages with PA66(strengthened with glassfiber) and PEEK. POM and PEEK materials are suitable for precision processing. The precision and tolerance of plastics bearings made of POM and PEEK are higher than that of traditional plastics bearings. Precise and high speed rotation working conditions are applicable.

3、Acid/alkali-resistant plastics bearings made with HDPE, PP, UPE, PE-UHMW, provide multiple solutions according to different application conditions. They have impressive resistence to acid, alkali, salt, solution, oil, gas and sea water, and ensure ideal durability and life expectancy.

4、Corrosion resistant bearings made with PTFE and PVDF are applicable in the environments of strong acid and strong alkali. PTFE can be used in all strong acid and strong alkali even in 98% fuming sulfuric acid and fuming nitric acid.

5、High temperature resistant bearing is made with PEEK and PI which are tested to be the ideal materials. PI can be used at 300°C in long term and at 350° in short term.

6、Main types of plastics bearings include deep groove bearing, self-aligning bearing, angular contact bearing, thrust ball bearing, insert bearing, plain bearing, cylindrical roller bearing, tapered roller bearing and housing. Other non-standard bearing and specific structure bearing are also available on customer’ s demand.

POM Polyoxymethylene can be used in temperatures ranging from -60°Cto +100°C. The high surface strength is only surpassed by few materials. POM shows good sliding property and high resistance to wear and tear because of the high strength and smooth surface. There is a very low risk of stress cracks. POM (Copolymere) exhibits a high thermal stability and a high resistance to chemicals (especially to hydrolysis).

Advantages

High hardness and rigidity

High toughness

Low water absorption

High dimension

Good electrical insulation property

Very good sliding property and high resistance to wear and tear

High resistance to solvents

Very high resistance to stress cracks

Disadvantages

Not resistant to high-concertrated acids and strong oxidant

Difficult to glue and paint

| 轴承零件 | 常用材料 |

| 内外圈 | POM,PA66 |

| 球 | POM,Glass,SUS440C,SUS304,SUS316 |

| 保持架 | PA66,POM,PP |

| Parts | Materials |

| Rings | POM,PA66 |

| Balls | POM,Glass,SUS440C,SUS304,SUS316 |

| Cage | PA66,POM,PP |

| Parts | Materials |

| Rings | POM,PA66 |

| Balls | POM,Glass,SUS440C,SUS304,SUS316 |

| Cage | PA66,POM,PP |

Polyether etherketone can be used at very high temperatures (+260°) and it shows an extraordinary mechanical strength, toughness, hardness, flexural strength, torsional strength, PEEK exhibits excellent chemical resistance, very good dielectric properties up to +260°C and a very good resistance to all kinds of radiation. Lmportantl it is self-extinguishing according to UL 94.

Advantages

Very high mechanical strength and rigidity

Very high toughness (also at low temperature)

Very high thermal stability

Very high anti-deformation ability at high temperature

Very high creep resistance

Very high dimentional stability

Very high resistance to roentgen ray and infrared ray

Very high hydrolysis resistance(18atm,280°C)

Disadvantages

Relatively low notched impact strength

Low resistance to acetone

| 轴承零件 | 常用材料 |

| 内外圈 | PEEK |

| 球 | PEEK,ZrO2,Sl3N4,SIC |

| 保持架 | PTFE,PEEK,PA66,UPE,PFA |

| Parts | Materials |

| Rings | PEEK |

| Balls | PEEK,ZrO2,Sl3N4,SIC |

| Cage | PTFE,PEEK,PA66,UPE,PFA |

| Parts | Materials |

| Rings | PEEK |

| Balls | PEEK,ZrO2,Sl3N4,SIC |

| Cage | PTFE,PEEK,PA66,UPE,PFA |

PVDF shows a higher tensile strength, pressure resistance and dimensional stability than related PTFE, but friction and insulation properties are lower. PVDF has a high mechanical strength and toughness at lower temperature and is self-extinguishing. It s woring temperature ranges from to -60°C to +150°C.PVDF is stable to chlorine, bromine and high energy rays. It can be corroded by ester and ketone solution at high temperature.

Advantages

High tensile strength

High tenacity

High chemical stability

Low water absorption

Good friction and wear and tear values

Self-extinguishing

High UV-resistance

Disadvantages

Toxic fumes when burned

Hard to be solvent cemented

| 轴承零件 | 常用材料 |

| 内外圈 | PVDF |

| 球 | PP,PTFE,SIC |

| 保持架 | PVDF,PP,PTFE |

| Parts | Materials |

| Rings | +PVDF |

| Balls | PP,PTFE,SIC |

| Cage | PVDF,PP,PTFE |

| Parts | Materials |

| Rings | PVDF |

| Balls | PP,PTFE,SIC |

| Cage | PVDF,PP,PTFE |

PTFE has long-term application temperature from -40°C to 200°C,has very strongly bears chemistry corrosiveness, to all chemicals all anti-corrosive,the friction ceofficient is low,has the good electric,certainly not temperature influence.

Advantages

High dimensional stability

Continuous working temperature-40°C~200℃

Surface friction coefficient 0.05~0.1,low dielectric constant

Anti-aging. Non-flammable,excellent resistencento adhesion

Resistance to strong acid, alkali ,salt and organic solvent

Mechanical property is good

Insulating property

Flame resistance, high safety level at high temperature

Disadvantages

Low fluidity

Unweldable

Difficult to melt processing

| 轴承零件 | 常用材料 |

| 内外圈 | PTFE |

| 球 | PTFE,PP,Class,ZrO2,Sl3N4,SIC |

| 保持架 | PTFE,PEEK |

| Parts | Materials |

| Rings | +PTFE |

| Balls | PTFE,PP,Class,ZrO2,Sl3N4,SIC |

| Cage | PTFE,PEEK |

| Parts | Materials |

| Rings | PTFE |

| Balls | PTFE,PP,Class,ZrO2,Sl3N4,SIC |

| Cage | PTFE,PEEK |

PP( Polypropylene ) shows a high mechanical strength, tensile strength, but a low notched impact strength, PP resists stress cracking and it is easy to weld. At low temperature it can get brittle. The chemical and electrical properties are very good. The temperature ranges between +5°Cand +100°.

Advantages

Low density

Good heat resistance, non-deformation

High tensile strength

High surface strength

High chemical stability

Non-poisonous

Disadvantages

Common tenacity

Common oxidation resistance

Common abrasion resistance

HF-welding not possible

Difficult to varnish and glue

Low adhension and paint properties subject to weather restrictions

| 轴承零件 | 常用材料 |

| 内外圈 | PP |

| 球 | PTFE,PP,Class,ZrO2,Sl3N4,SUS304,SUS316,SIC |

| 保持架 | PP,PA66 |

| Parts | Materials |

| Rings | PP |

| Balls | PTFE,PP,Class,ZrO2,Sl3N4,SUS304,SUS316,SIC |

| Cage | PP,PA66 |

| Parts | Materials |

| Rings | PP |

| Balls | PTFE,PP,Class,ZrO2,Sl3N4,SUS304,SUS316,SIC |

| Cage | PP,PA66 |

Polyethylene terephthalate shows high tensile and mechanical strength hardness and toughnessjow friction and a high dimensional stability. PET may be used at temperatures ranging from -40 to +110

Advantages

High mechanical resistance and tensile strength

High surface strength

High dimensional stability

High toughness

Low coefficient of friction

Low wear and tear

High chemical resistance

Easy to varnish and polish

Good electrical insulating properties

Disadvantages

Limited dielectric properties

Sensitive to hydrolysis

Applications

Bearings,pumps,parts for housings,tank lids,cog wheels,insulators.

| 轴承零件 | 常用材料 |

| 内外圈 | PET |

| 球 | PTFE,PP,Class,ZrO2,Sl3N4,SIC |

| 保持架 | PP,PTFE,PEEK,PA66,UPE |

| Parts | Materials |

| Rings | PET |

| Balls | PTFE,PP,Class,ZrO2,Sl3N4,SIC |

| Cage | PP,PTFE,PEEK,PA66,UPE |

| Parts | Materials |

| Rings | PET |

| Balls | PTFE,PP,Class,ZrO2,Sl3N4,SIC |

| Cage | PP,PTFE,PEEK,PA66,UPE |

PCTFE has unique pro erties.Its resistance to cold flow.dimensional stability, rigidity, low gas permeability, and low moisture absorption are superior to other fluoropolymers.

Excellent low temperature properties

PCT FEat low temperature and high mechanical strength and a low rate of output, thus can be widely used in machinery parts, and equipment used at low temperatures.

Maximumpressure: 10kg/cm

Applies: low temperature fluid and gas, LNG, LPG, etc

Use temperature: -250℃to room temperature

Production item: Max.o 230

Good mechanical characteristics

Good compression strength and deformation rate is low

Chemical resistance is strong

For strong acid, strong alkali acid mixture, acid ulan t resistance is good

Good electrical resistance(low dielectric constant)

| 轴承零件 | 常用材料 |

| 内外圈 | PCTFE |

| 球 | SIC |

| 保持架 | PCTFE,PTFE,PVDF |

| Parts | Materials |

| Rings | PCTFE |

| Balls | SIC |

| Cage | PCTFE,PTFE,PVDF |

| Parts | Materials |

| Rings | PCTFE |

| Balls | SIC |

| Cage | PCTFE,PTFE,PVDF |

HDPE(High Density Polyethylene) There two Polyolefins offer resistance to almost all acids and bases, detergents and hot water.PE has good insulation properties and is easy to weld.The operating temperature of HDPE is from -50℃to+90℃.

Advantages

Lightweight

High toughness(also at low rem perature)

High elongation

Very good electrical and dielectric properties

Very low water absorption

Low steam per me ablity

High chemical resistance

Good protection against stress cracking

Food safe

Disadvantages

Soft surface(low tensile strength)

HF welding not recommended

Difficult to varnish and glue

Not weather resistant

| 轴承零件 | 常用材料 |

| 内外圈 | HDPE |

| 球 | Class,ZrO2,Sl3N4,PP,SIC,SUS304,SUS316 |

| 保持架 | HDPE,PA66,PP |

| Parts | Materials |

| Rings | HDPE |

| Balls | Class,ZrO2,Sl3N4,PP,SIC,SUS304,SUS316 |

| Cage | HDPE,PA66,PP |

| Parts | Materials |

| Rings | HDPE |

| Balls | Class,ZrO2,Sl3N4,PP,SIC,SUS304,SUS316 |

| Cage | HDPE,PA66,PP |

Its muy buenas propiedades des liza mien to than HDPE.

| 轴承零件 | 常用材料 |

| 内外圈 | PE-UHMW |

| 球 | Class,ZrO2,Sl3N4,PP,SIC,SUS304,SUS316 |

| 保持架 | PE-UHMW,PA66,PP |

| Parts | Materials |

| Rings | PE-UHMW |

| Balls | Class,ZrO2,Sl3N4,PP,SIC,SUS304,SUS316 |

| Cage | PE-UHMW,PA66,PP |

| Parts | Materials |

| Rings | PE-UHMW |

| Balls | Class,ZrO2,Sl3N4,PP,SIC,SUS304,SUS316 |

| Cage | PE-UHMW,PA66,PP |

0573-87995823

18969340002

18957331003

13957310003